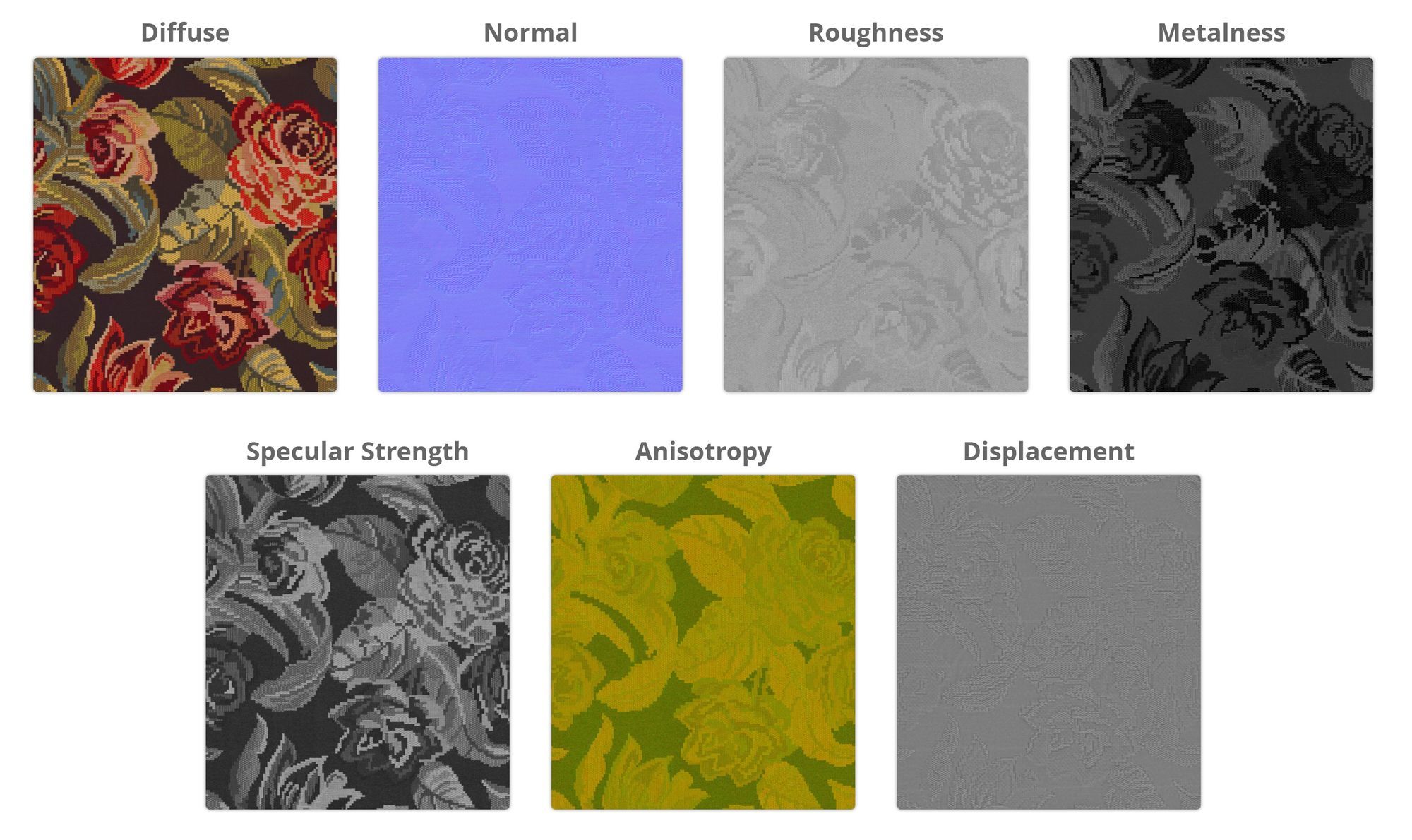

When selecting scanner technology to digitize your fabrics/materials, it is important to understand that PBR material scanning is more of a general term. Even though these technologies share the same name, the final output quality can vary significantly.

These technologies can be categorized into two groups based on the complexity of their capture and adaptation algorithms:

- Simple Scanning

- Complex Scanning

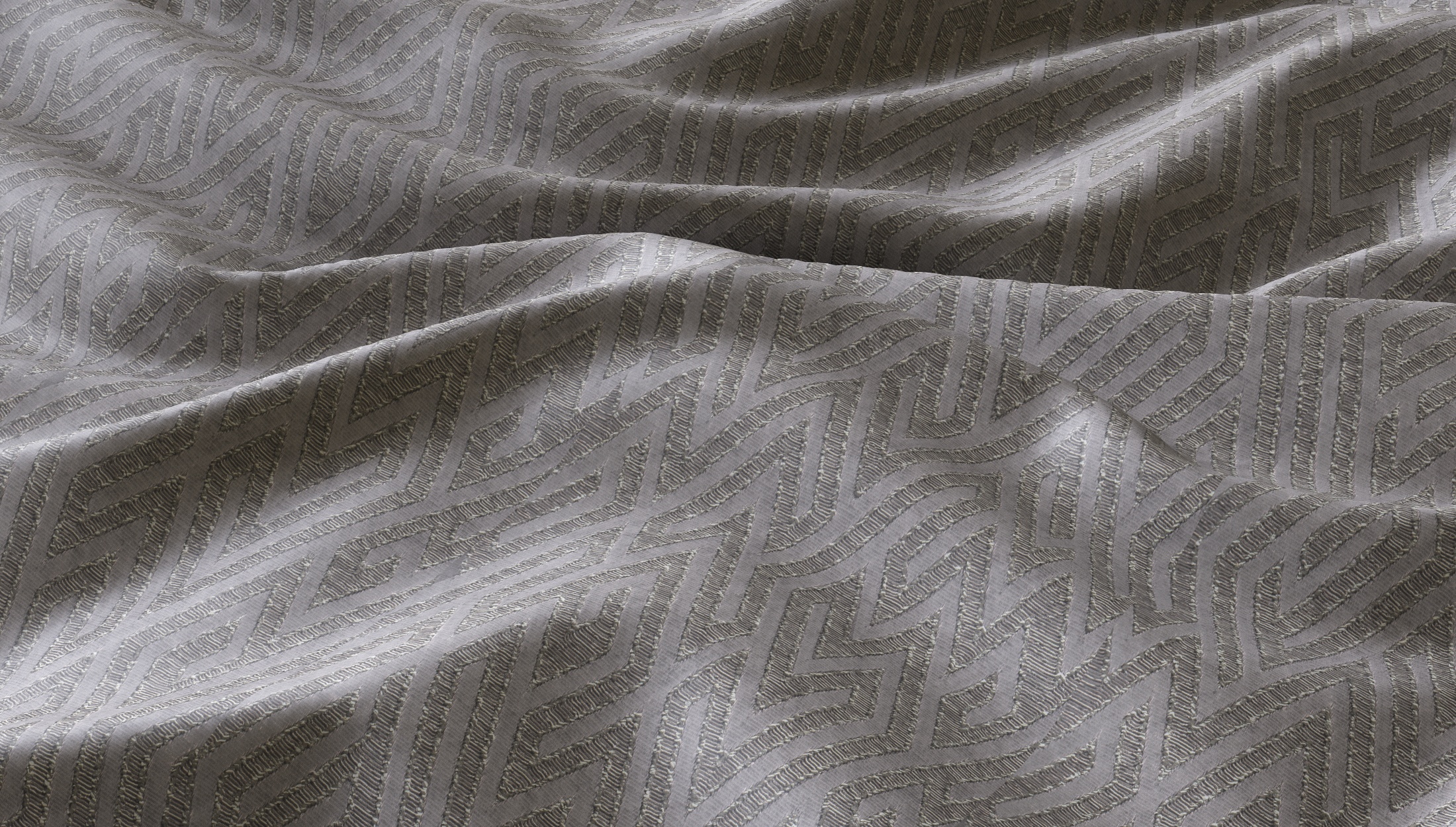

The first visible difference is that simple scanning takes approximately 10-20 minutes to capture and create a digital material, while complex adaptation can take 8-12 hours to achieve the final digital material. More importantly, the real difference lies in the quality of the final visuals. Below, you can see a comparison.